Alcon Mechanical in Niles believes that creating partnerships is the best way to serve the community. The company hopes to continue building on that mission now that it’s joined Mahoning Valley Manufacturers Coalition.

Bob Summers, director of development at Alcon, wants people to know the company is familiar with manufacturing and is glad to already be serving businesses that are also members.

“We are equally focused on promoting MVMC and what the organization does – just as it recognizes Alcon. Ultimately, this leads to benefits for both parties. There’s more to Alcon than just mechanical work,” Summers said.

A history rooted in partnership

The company has been around for nearly 30 years and serves mainly commercial and industrial clients in northeast Ohio and into Pennsylvania. It’s licensed and certified to perform process piping, HVAC and hydronics, plumbing and food equipment service. There are 125 employees – which include two engineers and 12 people in the front office.

Alcon isn’t hiring right now, but owner and president, John Deraway, sees the challenge ahead of not having enough veteran, skilled workers.

“We’re facing issues like other companies. The aging, skilled workforce is retiring. We’re training the new people as fast as we can, but there’s going to be a gap that isn’t going to be filled. It takes time to make these employees,” Deraway said.

He got his start as a pipefitter, then worked his way up at the company for more than 20 years. Deraway bought Alcon in 2019 from George Poschner Jr. whose family also worked at there.

In the early days, Alcon was called Commercial Piping and partnered with Diamond Steel and Compco Industries before all the companies went on their own. About a decade later is when Commercial Piping changed its name to Alcon Mechanical.

On-site service

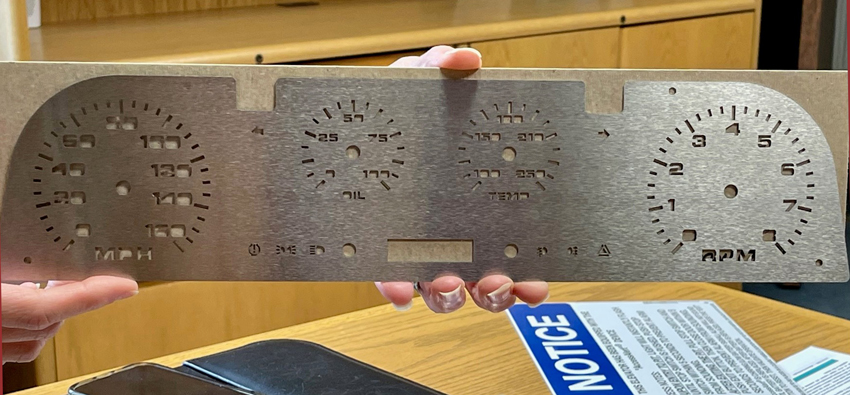

When it comes to fabricating products for customers, a lot of work is done at the job sites.

“Before we make anything, we have conversations with everyone on the ground to make sure they can handle it. There’s a lot of coordination, and our engineers do all the logistics,” Summers said.

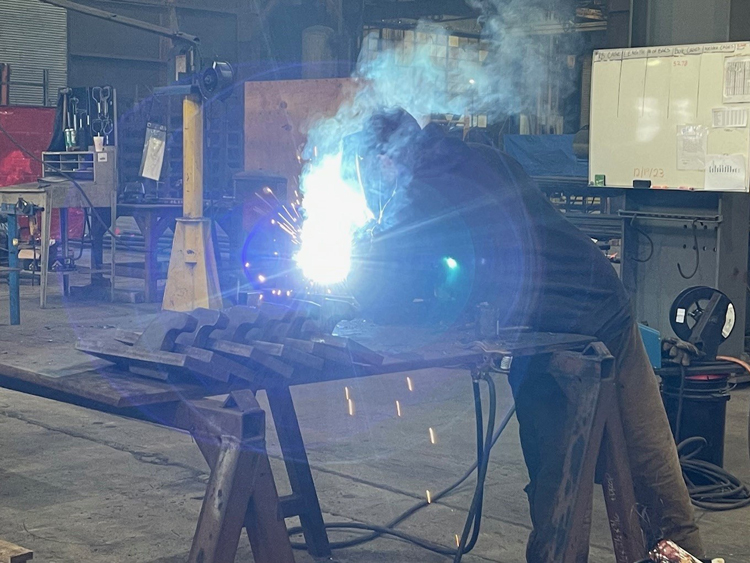

He says the advantage of working on site means they can roll with changes and eliminate the possibility of extra costs to a project. Summers added that Alcon does quite a bit of welding when it comes to parts. Those are typically then shipped or transported to customers.

Big name projects

One of the most significant projects for Alcon, which is still in the works, is the Ultium Cells battery plant in Lordstown. Summers says the mechanical contract went to a Michigan company, but for Alcon, it was a case of being at the right place at the right time.

“I ended up getting ahold of the main coordinator, and through that, he offered us work. Although we didn’t do all the mechanical work, we were the first area mechanicals to be working there, besides the Michigan company,” Summers said.

The work is still going on at Ultium. Summers says many of the plans from a few years ago in terms of EV batteries changed, so the companies recently worked together to make adjustments.

Alcon is also planning to work on Ohio’s new Intel plant in Columbus. The company will be supplying piping systems for chemicals and the gas lines. The hope is to make most of the products at Alcon and then ship them to the site. The company has also done significant projects for Howmet Aerospace and NLMK Steel.

Implementing health and safety initiatives

There are two new initiatives for the company when it comes to health and safety. The first is advanced leak detection technology that Alcon hopes to offer customers. Management is working with the company Fluke to learn the system and how it can be implemented for local businesses.

“We can walk into plants with a handheld device to see where leaks might be,” Summers said. “The results will show how much is being lost, return on investment, as well as how much it would cost to fix the problem.”

He stresses the most important aspect of this technology is knowing how it can affect a business from a health standpoint. Summers says even small amounts of certain gases or chemicals can be dangerous to people and the environment. Right now, Alcon is going out with engineers to learn how to detect issues and finding out what customers need most.

The company is also looking into a new-to-market air quality system. It uses plasma-style technology which creates ions that attach to contaminants. This makes it easier for them to be caught in a filter.

“Common sense tells you that if your work environment is better, people will be healthier, feel better and overall be more productive,” Summers said.

Keeping the service department steady

Looking to the future, the owner says the money is in the service department when it comes to a career.

“It’s going to get expensive, and it already is,” Deraway said. “You try to retain workers as best you can, but it’s just one of those things.”

He is fortunate to have stayed busy over the last decade but notes the continuous battle with a tight supply chain. Deraway is also always willing to jump in and work with the crew on a job.

“Sometimes it’s a break from what’s going on in the office. No one can say I don’t know how hard something is because I’ve done it,” he said.

He has some honest advice, too, when it comes to job seekers.

“Money shouldn’t be the first thing on the list when it comes to a job. If you can have a conversation with someone, shake someone’s hand, look them in the eye and stay off your phone you will flourish compared to everyone else,” Deraway said.

Training is the key to ensuring that the proper processes are taking place on the plant floor.

Training is the key to ensuring that the proper processes are taking place on the plant floor.