Trumbull Career and Technical Center’s industrial technology program is opening doors to exciting, in-demand careers in manufacturing.

It offers hands-on lessons, problem-solving and access to cutting-edge equipment.

The program launched in the 2024-2025 school year with 13 students participating. They’re earning industry-recognized credentials with a direct pathway into the workforce.

Laying the groundwork

The industrial technology program is part of an expansion of TCTC’s workforce development services. A groundbreaking ceremony was held in May 2025 for a new training and resources center, which is set to open in fall 2026.

The funding comes from a $5.2 million Appalachian Community Innovation Centers grant, and another $2.5 million state grant for equipment.

“Without the support of MVMC, we probably wouldn’t have been able to secure the funding,” said Anina Karlovic, TCTC career tech supervisor.

As manufacturers face a growing need for skilled workers, the program is designed to bridge the gap, preparing students to step directly into careers in machining, hydraulics, robotics, and more.

With strong industry support and a customizable curriculum, TCTC is redefining what career and technical education can offer.

Hands-on learning for real-world careers

Unlike traditional classroom settings, TCTC’s industrial technology program puts students in charge of their learning, allowing them to tailor their education to their unique career interests.

“We don’t force students into a one-size-fits-all model,” said John Pettit, TCTC industrial technology instructor. “If a student is passionate about robotics, they can focus on that. If they love machining, they can earn multiple machining credentials. The goal is to make sure they leave here not just job-ready, but excited about their future.”

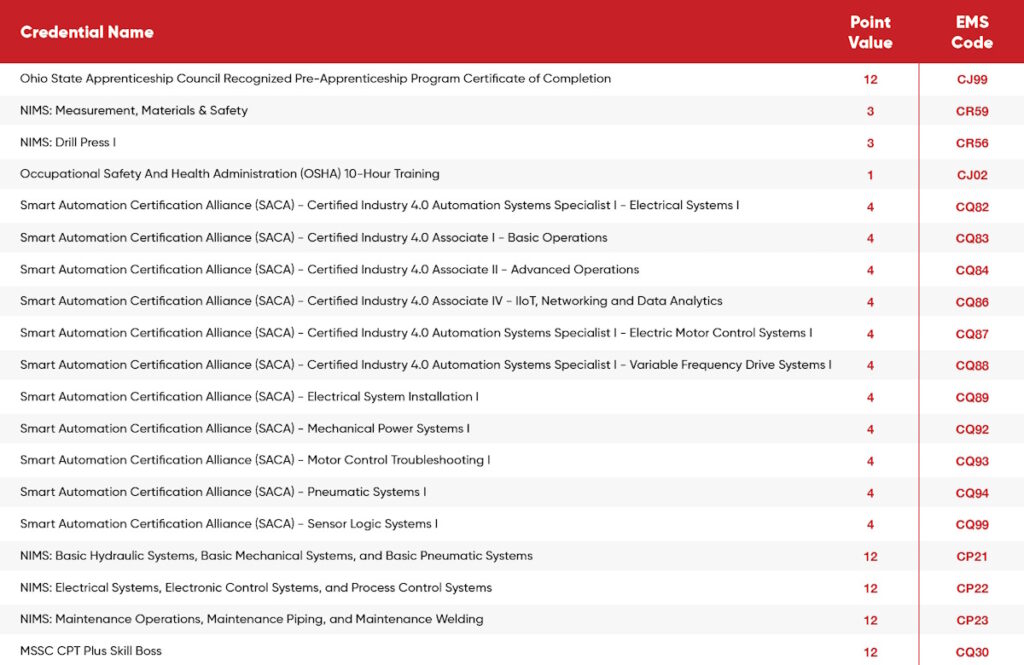

The program offers 111 industry credential points, allowing students to gain certifications in:

- Hydraulics and pneumatics

- Electrical systems and motor controls

- Machining and CNC programming

- Industrial maintenance and mechatronics

- Welding and safety compliance

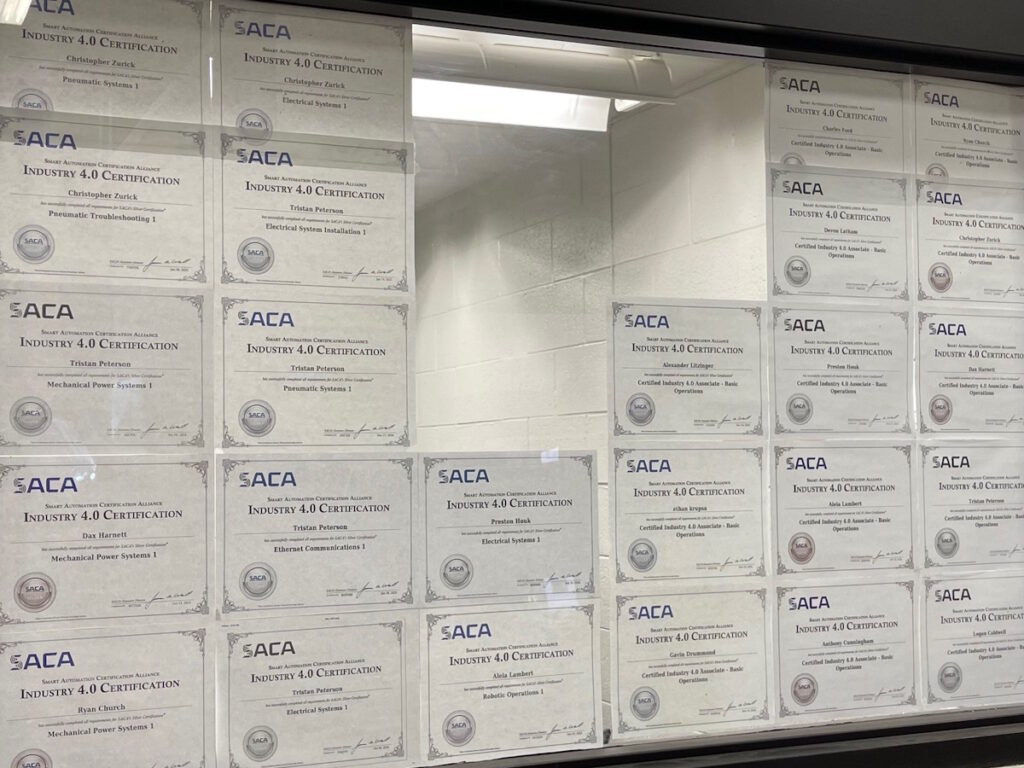

By the time students graduate, they have a resume filled with credentials that employers recognize and value, making them highly competitive in today’s job market.

“I don’t want students to just memorize information. I want them to actually understand how things work, how to solve problems and troubleshoot,” Pettit said.

One of his students recently put these skills to the test by designing and machining custom wrenches to work on his dirt bike.

“He programmed them, cut them, and then used them to take his bike apart. That’s the kind of real-world application that makes learning exciting,” Pettit said.

Importance of employer participation

TCTC’s program is also a game-changer for local manufacturers seeking skilled workers. Foxconn and Dinesol Plastics have already interacted with students, providing hands-on exposure to manufacturing careers.

“The success of this program depends on industry involvement,” said Paula Baco, TCTC director. “We’re building the next generation of skilled workers, and we need local employers to help shape that workforce by engaging with our students early and often.”

For employers, this is a golden opportunity to invest in the workforce of tomorrow by partnering with TCTC.

“The program is producing motivated, highly skilled young professionals that have customized career pathways that align with company needs,” said Alex Hertzer, Executive Director of MVMC. “Employers who engage with these students now will have a direct pipeline to the best talent in the region.”

The industrial technology program is not only an education, but also a launchpad for students to step into the best possible careers in modern manufacturing.